Hezarazar

We specialize in explosive welding, a technique that securely attaches similar or dissimilar metals through precisely controlled explosions

Explosive welding solutions

About us

For over 20 years, Hezarazar has been a leader in metal innovation. Recently relocated to Canada, we are now proudly serving the Toronto GTA. Our explosion welding method joins different metals with precision, creating reliable and efficient solutions for various industries.

Unlike traditional welding, our approach avoids common defects, ensuring a solid connection without compromising mechanical properties. With a track record of hundreds of successful projects globally, Hezarazar is your trusted partner for all your welding needs in the Toronto GTA and across Canada.

Explosive welding demonstrates remarkable versatility by bonding dissimilar and typically unweldable metals, facilitating the efficient joining of extremely large surfaces while preserving the original mechanical properties of the parent metals

Explosive welding

Explosive welding represents a metallurgical fusion where a bond between two metals is meticulously forged through the energy of controlled explosions while maintaining a solid state. The key to achieving a robust metallurgical connection lies in satisfying two critical conditions:

- On an atomic scale, the selected metal surfaces must be intimately close.

- These metal surfaces must be free of impurities on an atomic scale.

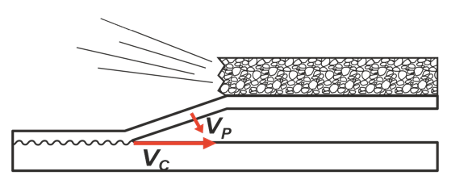

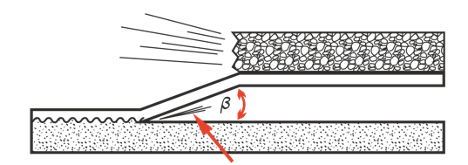

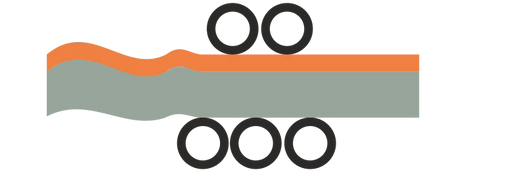

Thanks to the unique nature of explosive welding, we seamlessly fulfill both conditions simultaneously. Our specially designed process arrangement, as illustrated in Figure 1, ensures complete contact between metals, propelled by their high collision speed.

Figure 1: The arrangement of primary elements and the display of velocity directions in explosive welding.

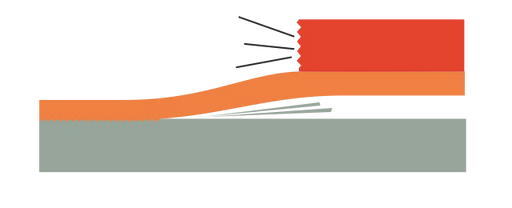

As the shockwave from the explosion travels across the upper metal plate (flyer) and speeds up toward the base plate (Backer), minute layers are delicately stripped away from each surface. This meticulous cleansing occurs just before contact (Figure 2), ensuring an intricate process that culminates in a flawlessly pristine connection.

jetting phenomenon

Figure 2: Removal of particles from metal surfaces during the jetting process.

Steps of Explosive Welding

Explosive welding finds its application in connecting a wide array of metal compounds. The primary consideration is to manage hardness within permissible limits, preventing unwanted fractions or cracks due to the blast wave. Moreover, maintaining optimal ratios between the process's key variables is crucial for constructing a durable connection.

Assembling plates: Consideration of stand-off distance and strategic placement of explosives on the clad plate sets the stage

Preparing and cleaning surfaces: The foundation of a flawless connection begins with immaculately prepared surfaces

Explosion: The orchestrated burst of energy brings metals into a harmonious union.

Flattening, cutting, and complementary processes: The final touches to ensure a perfect finish

Explosive Welding Under the Lens

Aluminium

Titanium

Copper

SS 316

A516 Gr.70

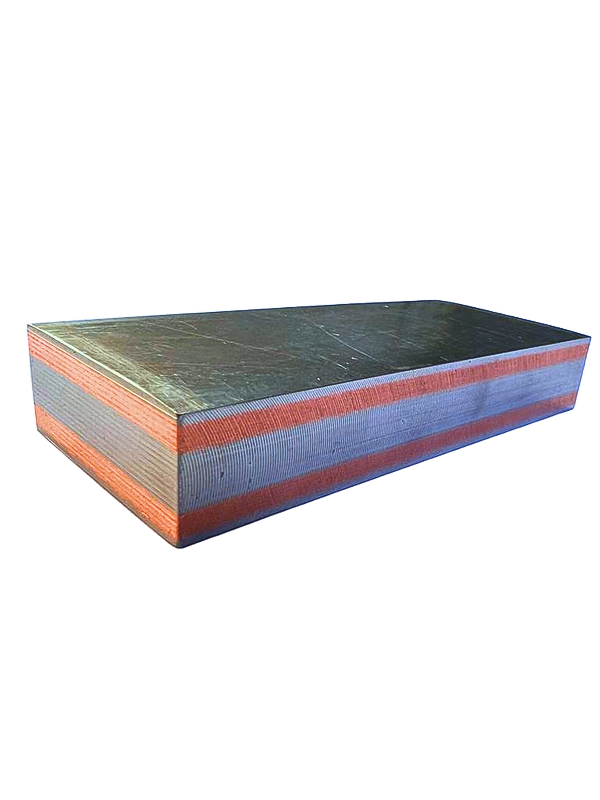

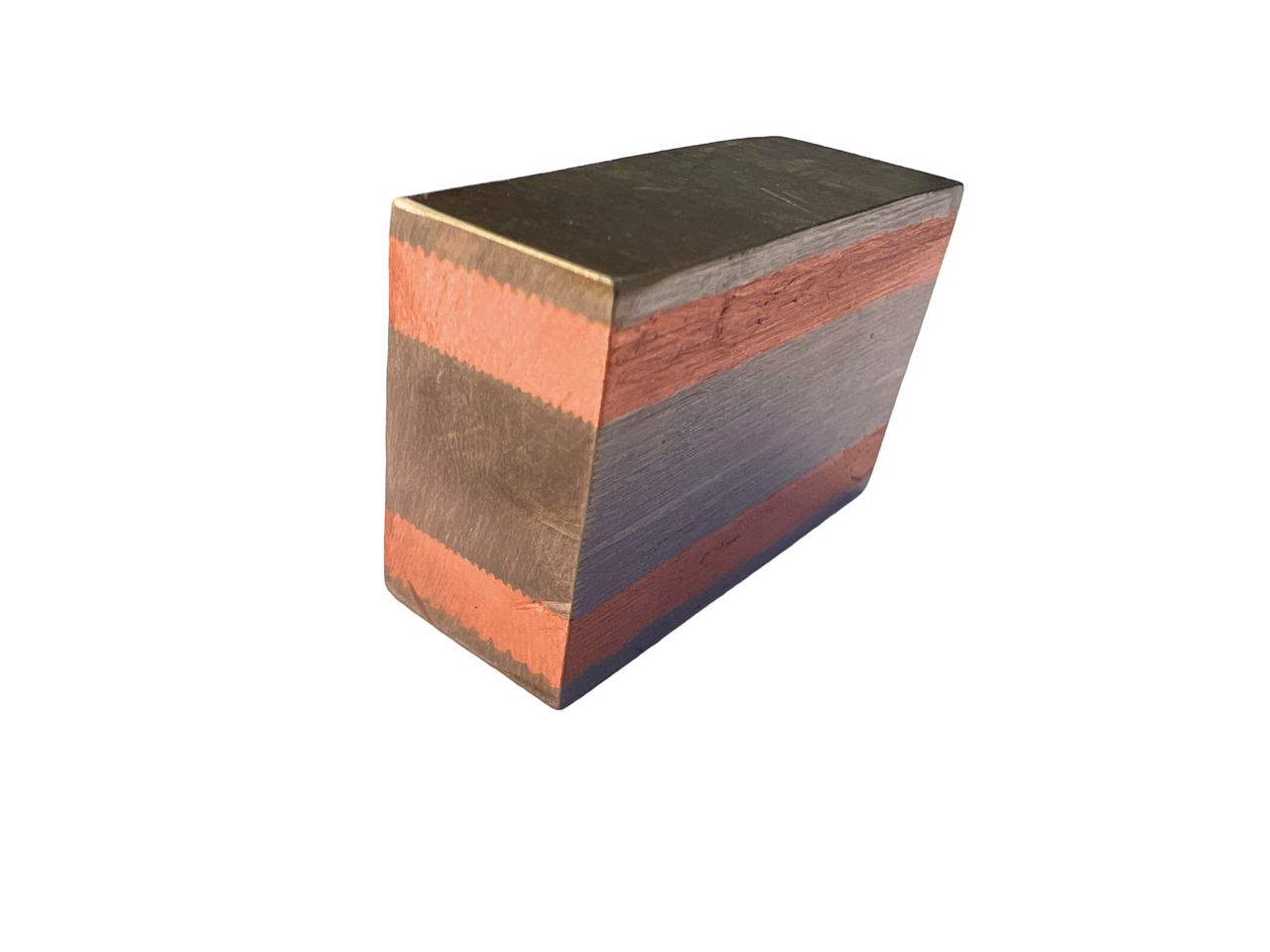

products

Flyer: Stainless Steel 420

Base Layer: chromium-molybdenum steel

Flyer: Copper

Base Layer: S355J2

Flyer: Aluminum + Int.Layer Titanium Gr.2

Base Layer: S355J2

Flyer: Copper

Base Layer: Aluminium

Flyer: Copper

Base Layer: Aluminium

Flyer: Aluminium 5000 Int. Layer Aluminium 1000

Base Layer: Stainless Steel 316

Flyer: Titanium Gr.2

Base Layer: S355J2

Flyer: Copper + Int. Layer Titanium

Base Layer: Aluminuim